Laser cutting has important advantages for sailmakers who can cut Dacron by cauterizing the edges of the panels, it also allows you to cut very difficult materials and to keep the scissors very close to each other, with a significant saving of material. However, it is necessary to take into account an objective greater complexity of managing the machine compared to blade cutting, in terms of fumes to be disposed of correctly and training of personnel in the danger of the system if correct operating procedures are not followed.

The laser version of the Bravearm-MMX architecture was first built in version Laser + Lama, overcoming some difficulties inherent in the incompatibility of the two cutting systems.

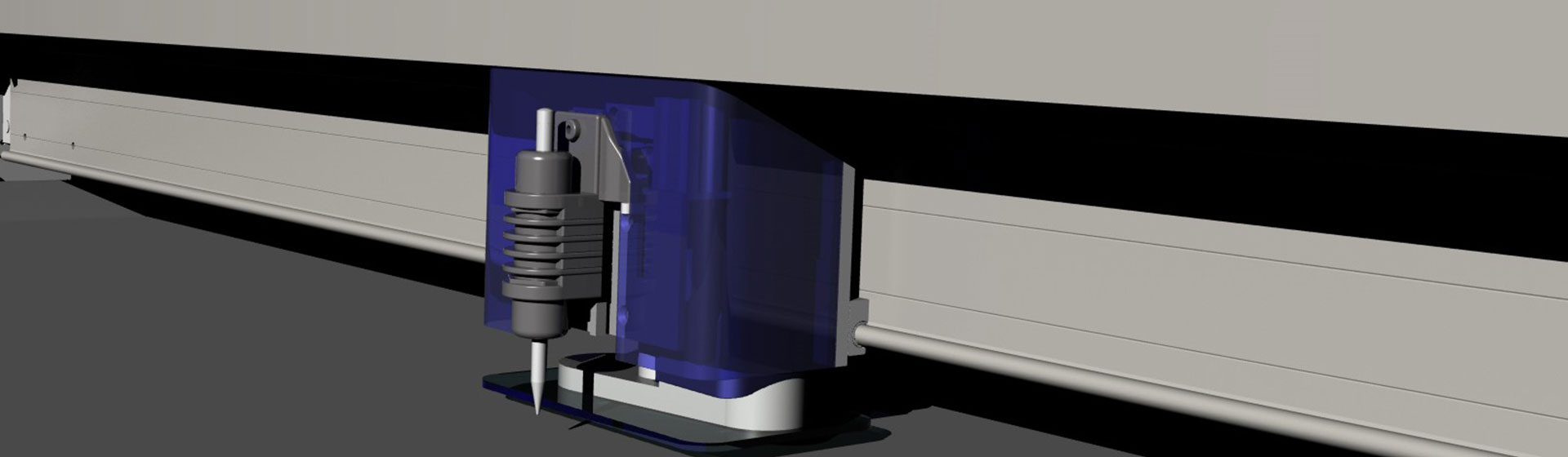

Based on the customer's actual use, that in the end he preferred to cut all the sailing material with the laser, we have designed a lighter and more compact plotter-cutter equipped with laser only, that enhanced the high cutting speed of light Spinnaker fabrics while retaining the power for more difficult materials such as Kevlar or Dyneema.

Our laser cutter uses glass CO2 laser tubes of the best brand in the world, with exceptional power and durability, easy to maintain and cool, that does not need the very tight specifications of radiofrequency excited lasers and their expensive and delicate power supplies.

During the installation of the laser system we provide to train the customer on the adjustment and calibration of the mirrors, which must be performed from time to time.

When, after 3-4 years of work you will have to replace the laser tube, as is the case with all types of lasers, the expense will be very low and the assembly very simple.

General features

● Custom workspace size

● Cutting width up to 2,0 meters

● Universal pneumatic pen holder

● Adjustable cutting speed

● Program in 4 languages

● CAD drawing format: DXF (std)

● Sail drawing formats: NTV-DXFAAMA-GERBER

● Nesting with mouse and keyboard

● Setting of machining sequence

● Digitizer (optional)

● Vacuum table

● Table with aluminum profile structure

● Smoke extractor : included and integrated

● System with CE marking

● High quality / price ratio

Technical features

► Laser CO2 – 100-120 W

► Long life laser (8000 hours)

► Maximum speed 1000 mm/s

► Position accuracy max 0,15 mm

► Hybrid step motors with high torque and efficiency

► Motor drivers with microstep control

► Linear guides with technopolymer slides

► Ultra-filtered and adjustable laser assistance air

► Force vacuum up to 4,0 Kg/dm2

► Aluminum cutting surface 2 mm perforated

► Thermostated liquid laser cooling.

Requested services

► 1400W @ 220VAC plotter-cutter electrical panel

Dimensions 65 h x 40 x 20 cm

► Extractor power supply 3,0 – 5,5 Kw @ 380VAC

► Vacuum fan 3,0 – 5,5 Kw @ 380VAC

► Compressed air 6 bar; consumption 10 liters/min

► Fume extractor : 1200 W @ 220VAC